What is CNC Milling ?

CNC milling is a machining method where Material is removed from a workpiece using computer numerical control technology to control the movement of cutting tools on the material's surface. It leverages the precision and flexibility of CNC machines to efficiently produce complex geometric shapes and intricate surface structures, widely used in part manufacturing, mold making, prototyping, and other industrial applications.

Working Principle of CNC Milling:

Computer Control: CNC milling machines are operated by computers. The operator uses specialized software to write programs that dictate the path, speed, and feed rate of the cutting tools.

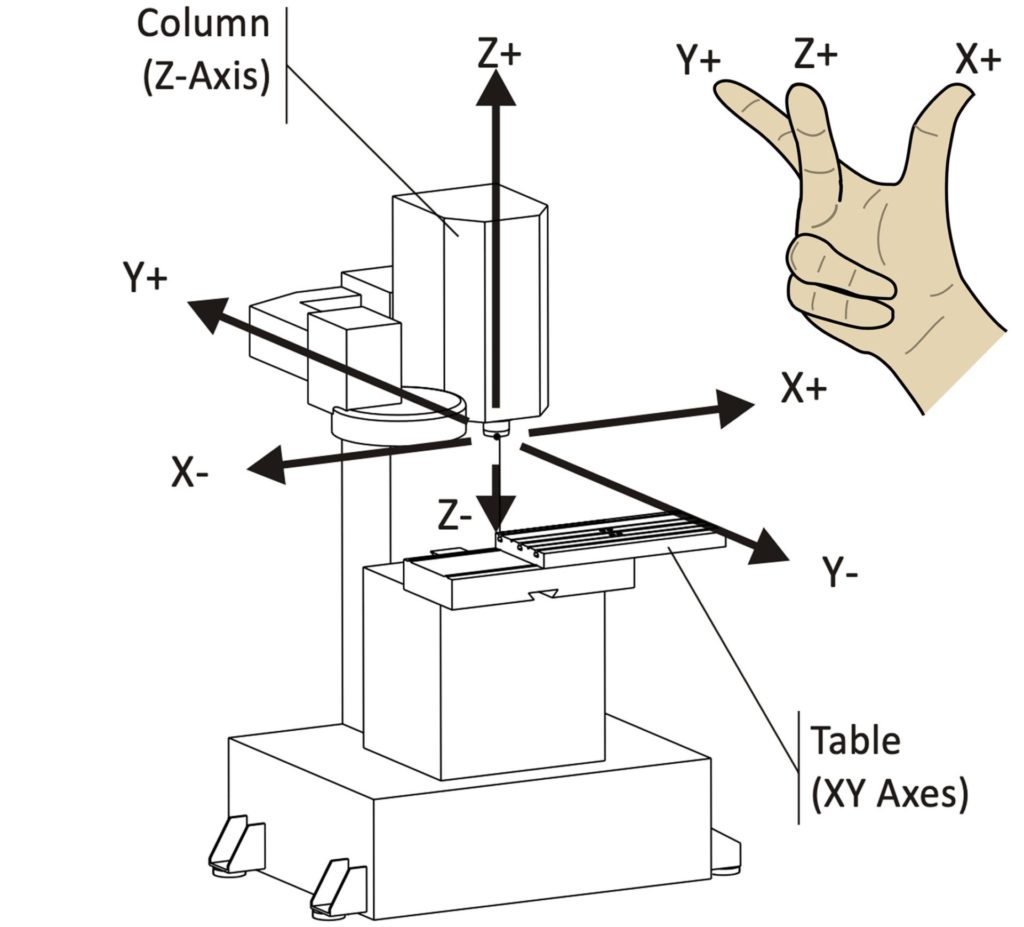

Tool Movement: The CNC milling machine is equipped with rotating cutting tools that can move in multiple directions (commonly X, Y, and Z axes). This movement allows for precise cutting and shaping of the workpiece.

Workpiece Fixing: The workpiece is securely fixed to the machine using clamps or a fixture. This ensures that the workpiece remains stable and does not shift or vibrate during the machining process.

Machining Process

Positioning: The CNC machine first moves the cutting tool to the starting position of the workpiece.

Cutting: The tool rotates and moves along the programmed path, removing material from the workpiece to gradually shape it into the desired form.

Cooling: During machining, coolant (such as cutting oil) is often used to reduce heat and friction, extend tool life, and improve machining quality.

Program Control: The CNC system uses G-codes and M-codes to control the speed, direction, and movement path of the tool, achieving high precision and complex shapes.

Types of Machines Used in Cnc Milling

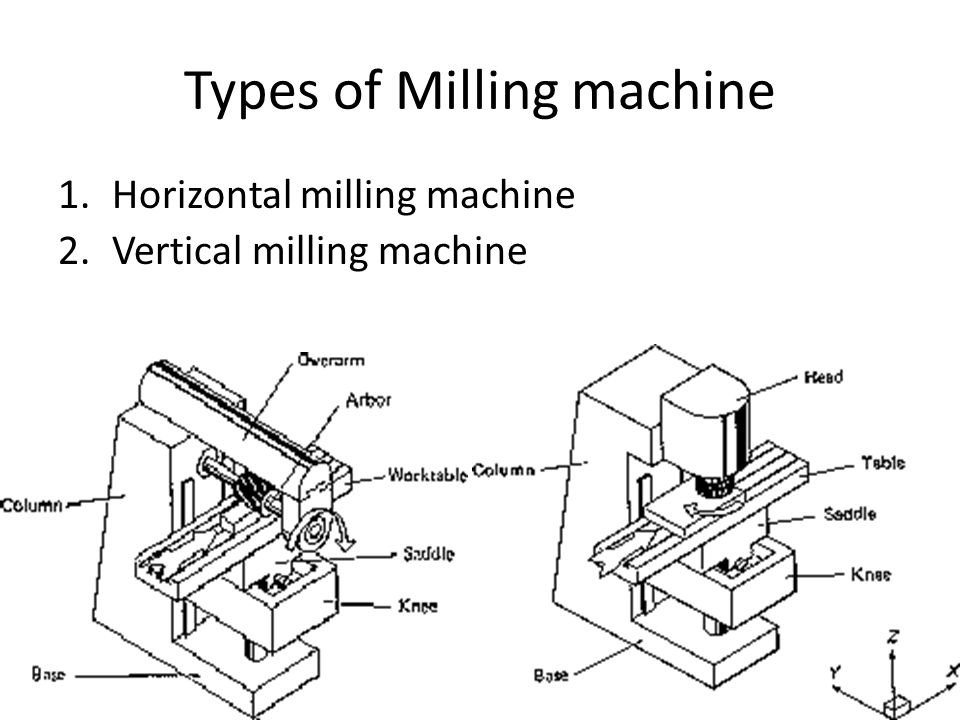

Vertical Milling Machines: These machines have a vertical spindle that holds the cutting tool. They are commonly used for tasks requiring precision and fine detail. The workpiece is usually mounted on a table that moves in horizontal directions (X and Y axes) while the spindle moves up and down (Z axis).

Horizontal Milling Machines: These machines have a horizontal spindle. They are ideal for heavy cutting and are used for larger workpieces. The horizontal orientation allows for the use of longer, more robust cutting tools.

Universal Milling Machines: These machines combine features of both vertical and horizontal milling machines, allowing for greater versatility. They can handle a variety of cutting operations and workpiece shapes.

CNC Routers: These are used for cutting softer materials like wood, plastics, and composites. They are similar to CNC milling machines but are often used for larger, flat workpieces and can perform a range of cutting, drilling, and engraving tasks.

5-Axis Milling Machines: These advanced machines can move the tool or workpiece along five axes simultaneously. This capability allows for complex geometries and high-precision parts, making them suitable for aerospace, automotive, and medical Industries.

Swiss-type Lathes: While primarily used for turning, some models offer CNC milling Capabilities and are used for high-precision, small-diameter parts.

Each type of CNC milling machine is chosen based on the specific requirements of the machining task, including the material being cut, the complexity of the part, and the desired precision.

Features of JeaSnn's CNCMilling Services

We offer comprehensive precision machining capabilities within our 5,000 square-foot facility and have over 20 years of experience. JeaSnn’s advanced CNC milling centers enable efficient production of mechanical parts with various working ranges to handle a wide range of projects. We work with a variety of materials, including stainless steel, aluminum, brass, copper, and bronze, and can accommodate rapid prototyping and small-batch manufacturing. As an ISO 9001 and IATF16949 certified company, we are committed to delivering consistent, high-quality products and utilize the latest inspection technology, including Coordinate Measuring Machines (CMM), to ensure precision and quality.

Our dedicated team is available 24/7 to offer professional and reliable advice on CNC Machining solutions. We specialize in OEM/ODM CNC machining design services, including drawing, prototyping, and assembly solutions, tailored to your specific needs. Additionally, we ensure precise packaging of machined parts to prevent damage during shipping and reduce your storage costs. Whether you provide designs or samples, our expert R&D team is ready to turn your concepts into high-quality products.

If you have any needs or inquiries, please feel free to contact us.

English

English