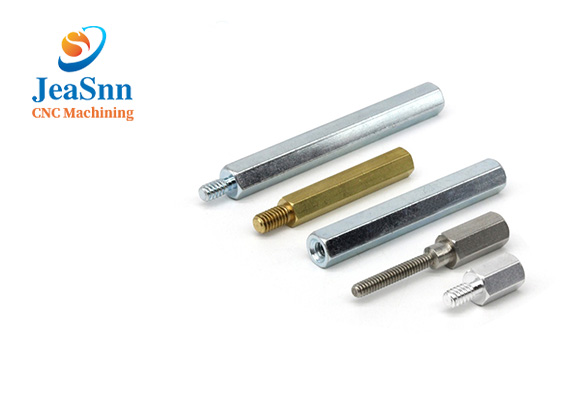

Male Female Threaded Hex Standoffs are important fastening components widely used in electronic products, PCB assembly, industrial equipment and other fields. They are used to fix PCBs or other components to the case or frame, and are often used to ensure that there is proper clearance between electronic components to avoid short circuits and damage. Male Female Threaded Hex Standoffs are available in male and female thread forms, and the hexagonal shape design makes them easy to install and remove. As a professional PCB support manufacturer, JeaSnn is able to provide large-scale precision-produced Male Female Threaded Hex Standoffs with advanced production processes and efficient production Capabilities.

Design and Structure of Male Female Threaded Hex Standoffs

Male Female Threaded Hex Standoffs usually adopt a hexagonal structure, which makes it easy to fix with a wrench during installation. The male thread (Male) part is usually used to install on the base of the female thread (Female) part to form a solid connection. The hexagonal design also enhances the torsion resistance of the support, ensuring its stability under high load or vibration environments.

The process of producing Male Female Threaded Hex Standoffs involves precision machining technology, and common machining equipment includes:

CNC lathe: CNC lathe is used to cut metal Materials and accurately process the shape and thread of the support through the CNC system. The lathe can accurately control the diameter, length and shape of the parts and maintain high-precision tolerances.

CNC Milling machine: used to process the fine parts of the support, such as the positioning of the hexagonal shape and threaded holes, to ensure the geometric shape and thread accuracy of the support.

CNC tapping machine: used to accurately cut the female thread (Female Thread) to ensure the quality and consistency of the thread.

Automated thread cutting machine: Precisely thread the support to ensure that the size, shape and load-bearing capacity of each thread meet the standard.

Through these precision equipment, JeaSnn can achieve efficient production and high-precision processing of Male Female Threaded Hex Standoffs, ensuring the high quality of each part.

Male Female Threaded Hex Standoffs can be produced using different materials to meet different application requirements. Common materials include:

Aluminum Alloy: Aluminum alloy is often used as support parts in electronic products due to its excellent corrosion resistance, low density and good processing performance. Aluminum supports are generally cost-effective and widely used in light-load applications.

Stainless Steel: Stainless steel supports have excellent corrosion resistance and high temperature resistance, and are suitable for environments requiring high durability and strength, such as industrial and medical equipment.

Brass: Brass supports have good electrical conductivity and are suitable for the requirements of conductivity in electronic applications, and brass materials are also highly corrosion-resistant.

Nylon: Nylon is a plastic material that is commonly used in light-load and corrosion-resistant electronic products. Nylon supports have good electrical insulation properties and are suitable for the assembly of electrical and electronic equipment.

Steel: Steel supports have high strength and wear resistance and are suitable for applications with heavy loads or high impact.

The choice of materials depends on the specific requirements of the application, such as corrosion resistance, load capacity, weight and conductivity.

The precision requirements of Male Female Threaded Hex Standoffs are very high, especially the accuracy of the thread is crucial for the tightening and firmness of the screw. Common precision requirements include:

Dimensional tolerance: Through CNC precision machining, the dimensional tolerance of Male Female Threaded Hex Standoffs can usually be controlled within ±0.05mm to ensure the dimensional accuracy of the support.

Thread accuracy: The precision requirements of the thread are very strict, usually need to meet the ISO 965-1 standard, and the accuracy of the thread can usually be controlled within ±0.1mm.

Geometric tolerance: The symmetry, roundness and verticality requirements of the hexagonal shape also need to be kept within a strict tolerance range to ensure the stability and assembly accuracy of the support.

Through precise processing equipment and strict quality control, JeaSnn can ensure the high precision of each support.

Surface treatment has an important impact on the service life and appearance of Male Female Threaded Hex Standoffs. Common surface treatment methods include:

Electroplating: Electroplating of metal layers such as nickel and chromium can improve the corrosion resistance, wear resistance and surface finish of the support, and is commonly used for stainless steel and brass support.

Anodizing: Especially suitable for aluminum alloy supports, anodizing can form a protective film to enhance its corrosion resistance and hardness, while also providing a variety of color surface effects.

Phosphating: Phosphating can form a phosphate protective film to enhance the corrosion resistance of the support and provide good adhesion for subsequent coatings.

Spray coating: Spray coating can provide additional corrosion protection and can be customized according to requirements.

These surface treatment processes not only improve the performance of Male Female Threaded Hex Standoffs, but also extend its service life and improve the appearance quality.

Male Female Threaded Hex Standoffs are widely used, especially when the PCB needs to be isolated from other devices or housings. The optimized processing process can be customized according to specific application requirements, including different sizes, materials and surface treatments. Common application areas include:

Electronic product assembly: In electronic products such as computers, televisions, mobile phones, and communication equipment, Male Female Threaded Hex Standoffs are used to fix the PCB in the housing, provide stable support, and ensure the safety of electrical connections.

Automotive electronics: In the electronic system of the car, the support is used to install the PCB on the vehicle control unit, sensor or display to ensure the stability and durability of the equipment.

Industrial control equipment: In automation, instrumentation, robots and other equipment, Male Female Threaded Hex Standoffs play a role in connection and isolation, ensuring the stable operation of the equipment under high load and high temperature environment.

Medical equipment: In medical equipment, precision supports are used to fix electronic components in the equipment, provide a stable working platform, and ensure the safety and long-term operation of the equipment.

Male Female Threaded Hex Standoffs have the following significant features:

High strength and stability: By selecting the right materials and surface treatments, the durability and stability of the supports can be ensured in various working environments.

High precision: CNC processing technology makes the size, thread and geometry of the supports extremely high precision, ensuring a perfect fit and a secure installation.

Widely applicable: Suitable for multiple Industries such as electronic products, mechanical equipment, automobiles, medical devices, etc., meeting various high standards.

Application scenarios:

Electronic products and equipment: such as computers, mobile phones, monitors, etc., especially those that require high precision and stable installation.

Automation and industrial equipment: such as sensors, robots, and automatic control systems, applications that carry loads and reduce vibration.

Medical equipment and instruments: environments that require high stability and precision to ensure the long-term reliability of electronic components.

As a professional Male Female Threaded Hex Standoffs manufacturer, JeaSnn provides high-precision and high-strength supports through precision processing equipment, strict quality control and advanced surface treatment technology, which are widely used in electronics, automobiles, medical and other industries. Whether it is high load, corrosion resistance, or applications that require precise installation, JeaSnn can provide customized solutions to ensure that each support can perfectly meet customer needs.

English

English